Do you know how Chinese PCB manufacturers control the finished copper thickness of the PCB?

PCB production process is relatively long, then the copper thickness of the PCB will have corresponding changes in each process. For example, there will be a fixed loss when the inner layer circuit is subjected to the pre-treatment processing, and the outer layer copper thickness will be increases accordingly after plating. So how China PCB manufacturers control the finished copper thickness of the PCB ?

The China PCB manufacturers include Shenzhen Vip Circuit Co,. Ltd. are follow the IPC-A-600G which is the acceptance standard for printed circuit board to control the PCB finished copper thickness. IPC-A-600G devide into 3 class namely class 1, class 2, class 3. The most demanding one is class 3, the most commonly used is class 2.

Please see the following pictures for detail which are from the IPC-A-600G :

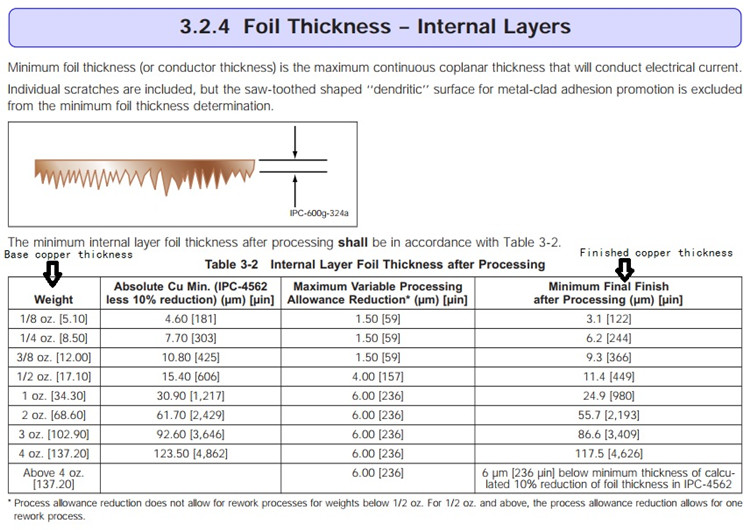

Acceptance standard for finished copper thickness of outer layer after plating :

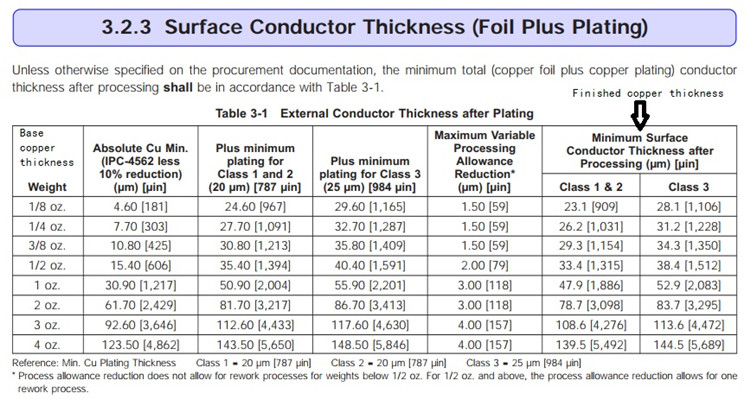

Acceptance standard for finished copper thickness of inner layer without plating :