The feature of LED Aluminum base board

The heat problem of LED is the most troublesome problem for LED manufacturers.Using aluminum base board, be due to aluminum thermal conductivity is high, heat dissipation is good, can effectively export the internal heat. Aluminum plate is a unique metal-based CCL, with good thermal conductivity, electrical insulation properties and mechanical processing performance. Design should also try to place PCB near the aluminum base,thereby reducing the thermal resistance generated by the potting process.

First, the characteristics of aluminum board

1. Using surface mount technology (SMT);

2. Extremely effective treatment on thermal diffusion during circuit design

3. Reduce the product operating temperature, improve product power density and reliability, extend product life;

4. Reduce product size, reduce hardware and assembly costs;

5. Replace the fragile ceramic substrate, get better mechanical durability.

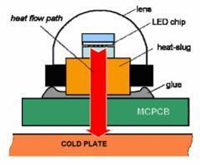

Second, the structure of the aluminum board

Aluminum-based CCL is a metal circuit board material, composed by copper foil, thermal insulation layer and metal layer, its structure is divided into three layers:

Circuit Layer: The equivalent of ordinary PCB CCL, copper foil thickness loz to 10oz.

Insulation layer: Insulation layer is a layer of low thermal resistance and thermal insulation material.

Base layer: is a metal substrate, usually aluminum or Cu. Aluminum-based CCL and the traditional epoxy glass cloth laminates and so on.

Circuit layers (ie, copper foil) are usually etched to form a printed circuit, make the component parts connected to each other, under normal circumstances, the circuit layer requires a large current carrying capacity, which should use thick copper foil, the thickness of 35μm ~ 280μm; thermal insulation layer is the core technology of aluminum base, which is generally made of special ceramic filled with special polymer, low thermal resistance, excellent viscoelastic performance, the ability to resist heat aging, can withstand mechanical and thermal stress.

High-performance aluminum board’s thermal insulation layer just used this technology, it has a very good thermal conductivity and high strength electrical insulation properties; metal layer is the support components of aluminum board, requires a high thermal conductivity, generally aluminum , or use Cu core (which Cu can provide better thermal conductivity), suitable for drilling, punching , cutting and other conventional machining. PCB material have incomparable advantages compared with other materials, Suitable for power components SMT. No need radiator, greatly reduced the size, excellent heat dissipation, good insulation and mechanical properties.

Third, the use of aluminum board

Uses: Power mixed IC (HIC).

1. Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

2. Power supply: switch regulator, DC / AC converter, SW regulator, etc.

3. Communication electronic equipment: high-frequency amplifier, filter , transmitting circuit

4. Office automation equipment: motor drives, etc.

5. Automotive: electronic regulator ,ignition, power controller, etc.

6. Computer: CPU board ,disk drive, power supply device.

7. Power module: converter ,solid relay, rectifier bridge, etc.

【Print】